Membrane Switch: A Comprehensive Guide to Its Uses and Applications

Wiki Article

Comprehending Membrane Layer Switches: The Key to Reputable and durable Controls

What Are Membrane Layer Buttons?

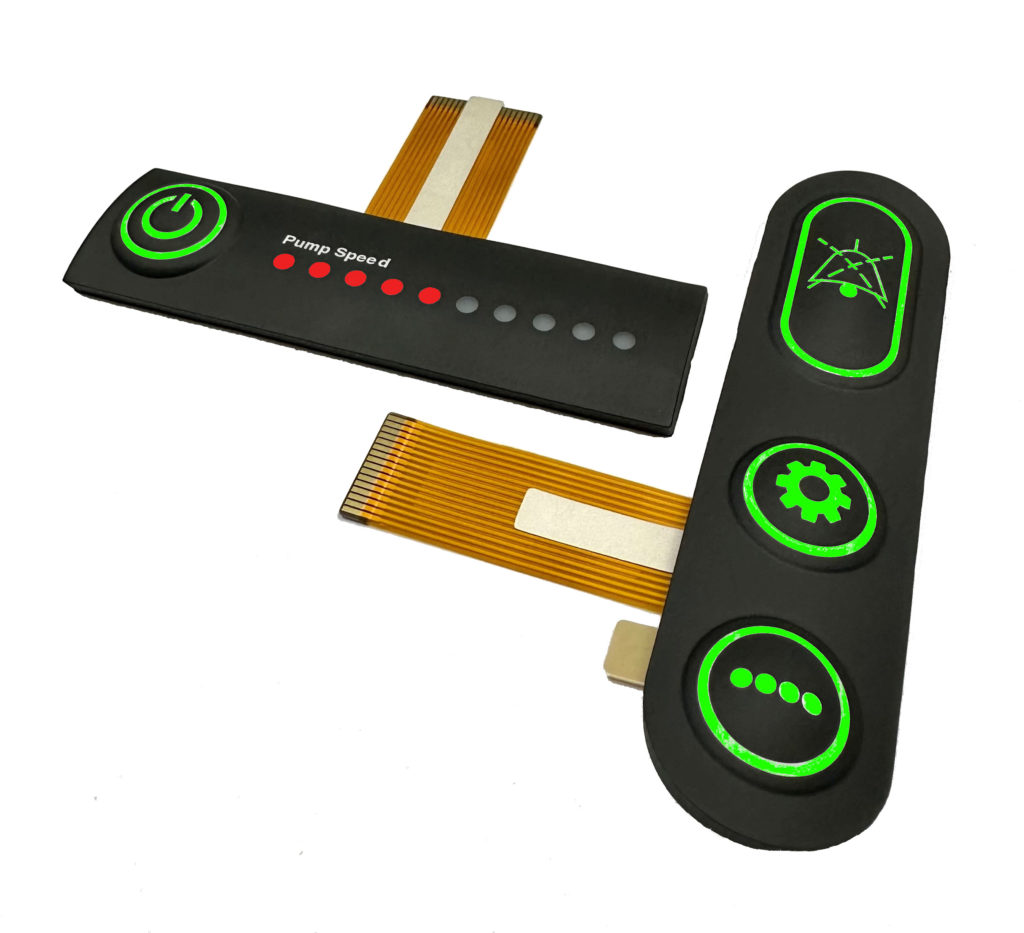

Membrane layer switches are an innovative service in the realm of individual interface modern technology, combining capability and design effortlessly. These gadgets serve as an interface in between users and electronic systems, integrating numerous elements into a small format. Commonly created from flexible, slim layers of materials, membrane layer switches are designed to respond to touch, making it possible for customers to connect with equipment and digital gadgets effectively.The main elements of a membrane button consist of a printed circuit layer, graphic overlay, and a spacer layer that avoids unexpected activation. The visuals overlay can be customized to reflect brand name identity or individual preferences, enhancing visual appeals while making certain use. Membrane layer switches are generally utilized in various applications, consisting of clinical devices, consumer electronic devices, and industrial devices, owing to their longevity and resistance to environmental factors such as wetness and dirt.

One of the vital benefits of membrane buttons is their ability to withstand deterioration, making them optimal for high-traffic environments. Additionally, they are light-weight and need minimal space, enabling for ingenious layouts in item advancement. In general, membrane changes represent a functional and effective choice for modern-day electronic user interfaces, marrying innovation with user-centric style principles.

Just How Membrane Switches Over Job

The procedure of membrane layer switches depend upon a straightforward yet effective device that equates customer input right into electronic signals. These buttons include numerous layers, generally including a graphic overlay, a spacer layer, and a circuit layer. When a user presses the button, the top layer warps, enabling a conductive aspect in the circuit layer to make contact with an equivalent conductive pad on the underside of the visuals overlay. This call shuts the circuit and sends out a digital signal to the tool, showing that the button has been triggered.The layout of membrane layer switches can vary, yet they commonly include domes or responsive aspects to supply responses to the customer, improving the general experience - membrane switch. The materials utilized in membrane layer switches, such as polyester or polycarbonate, contribute to their longevity and resistance to ecological variables, including moisture and dust. Additionally, the printed circuits are commonly encapsulated, which shields them from wear and tear in time.

Advantages of Membrane Layer Switches

Furthermore, membrane layer switches are recognized for their longevity. Built from durable products, they are resistant to dust, wetness, and physical wear, which considerably expands their life expectancy compared to typical mechanical switches. This durability makes them specifically suitable for high-traffic atmospheres and applications requiring longevity.

An additional considerable advantage is the ease of cleansing and upkeep. The directory smooth surface of membrane layer switches over reduces dirt build-up and is commonly resistant to spills, making them perfect for settings that require constant sanitization.

Furthermore, membrane buttons offer a structured profile, causing a thinner style that can be integrated right find here into different devices without adding mass. This attribute not just enhances the visual appeal however likewise contributes to a much more ergonomic item design.

Applications of Membrane Buttons

Straightforward and flexible, membrane layer buttons discover applications throughout a vast array of markets, consisting of clinical tools, customer electronics, and commercial devices. In the medical area, these buttons are indispensable to gadgets such as diagnostic devices, patient surveillance systems, and infusion pumps, where dependability and convenience of cleaning are crucial. Their capacity to endure severe settings and keep performance makes them perfect for such applications.

In consumer electronic devices, membrane layer buttons are made use of in products like microwaves, washing makers, and push-button controls - membrane switch. Their smooth layout enables for user-friendly interface, boosting the general individual experience while giving resilience and resistance to deterioration

Commercial devices likewise profits from membrane layer buttons, particularly in control panels for equipment and automation systems. These buttons use defense versus dirt and wetness, guaranteeing consistent efficiency in difficult environments. Furthermore, their adjustable functions allow suppliers to tailor them to details operational requirements, enhancing effectiveness and functionality.

Selecting the Right Membrane Switch

When choosing a membrane button, it is important to think about various elements that affect efficiency and suitability for particular applications. The main considerations consist of ecological conditions, tactile responses, resilience, and design requirements.

First, evaluate the operating atmosphere; buttons subjected to moisture, chemicals, or extreme temperature levels call for specific products to ensure longevity and capability. Next off, evaluate the demand for responsive feedback. Depending on individual communication, some applications may take advantage of a tactile response to verify activation, while others may like a non-tactile style for aesthetic factors.

Toughness is another essential variable; membrane switches need to be made to stand up to regular use, influences, and abrasion. Guarantee the chosen switch can endure the anticipated lifecycle, specifically in high-usage scenarios.

Conclusion

In verdict, membrane layer switches serve as important elements in the style of durable and trustworthy control systems throughout numerous markets. The versatility of membrane layer switches over allows for tailored solutions that fulfill details operational requirements, reinforcing their check my site significance in modern innovation.

Membrane layer changes represent a crucial aspect of modern-day interface style, mixing capability with resilience in numerous applications.Membrane layer switches are a sophisticated solution in the world of customer interface technology, incorporating capability and style seamlessly. Typically built from flexible, slim layers of products, membrane switches are developed to react to touch, allowing customers to communicate with machinery and digital devices properly.

The design of membrane buttons can vary, however they usually incorporate domes or tactile elements to give comments to the user, improving the total experience.In conclusion, membrane switches serve as essential components in the style of reliable and sturdy control systems throughout numerous sectors.

Report this wiki page